The JCC brand has become synonymous with fire-rated downlights. From the introduction of our Fireguard® GU10 range over 15 years ago, through to our current market leading V50™ and Fireguard® Next Generation, we have led the way in the design and development of fire-rated downlights.

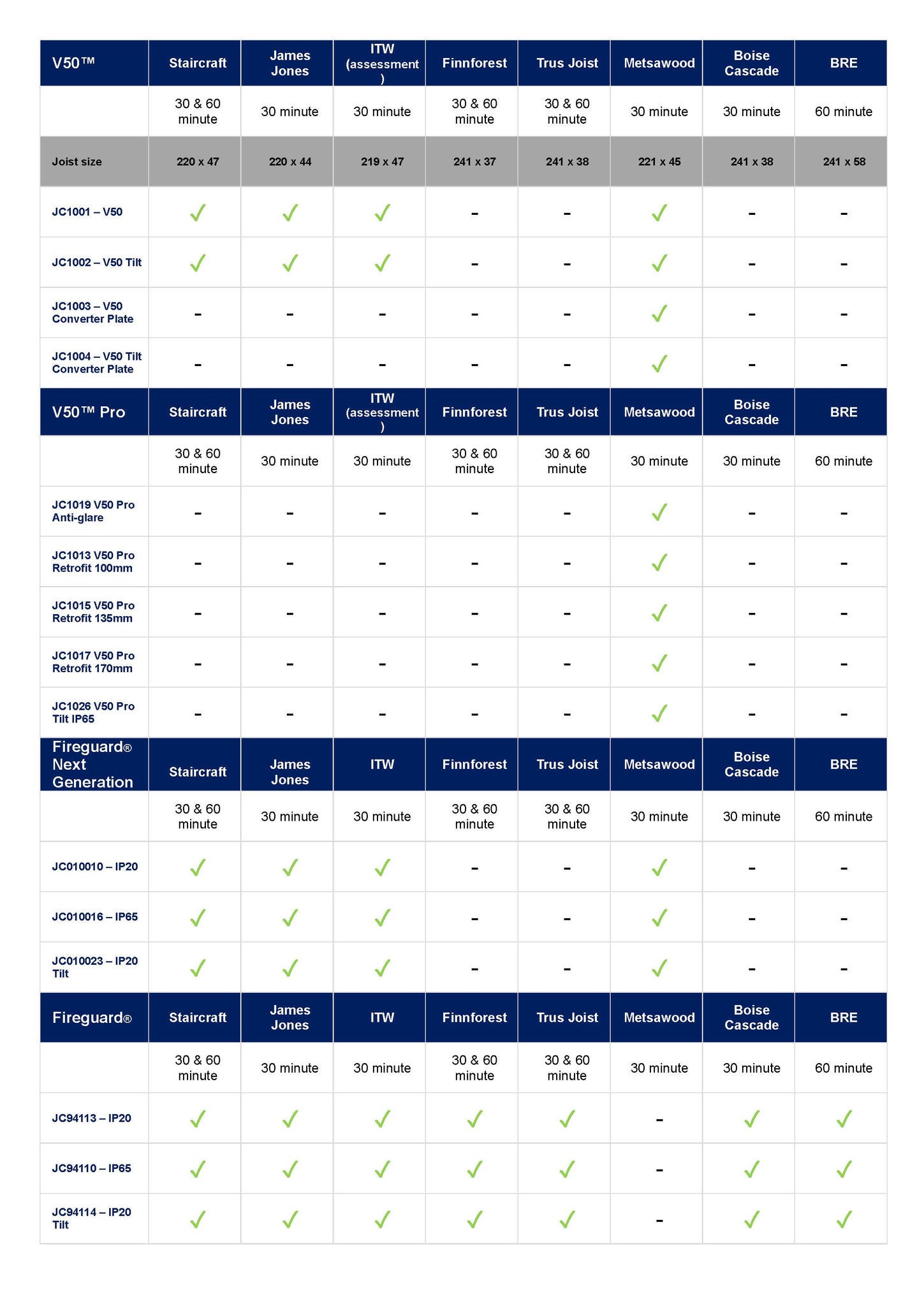

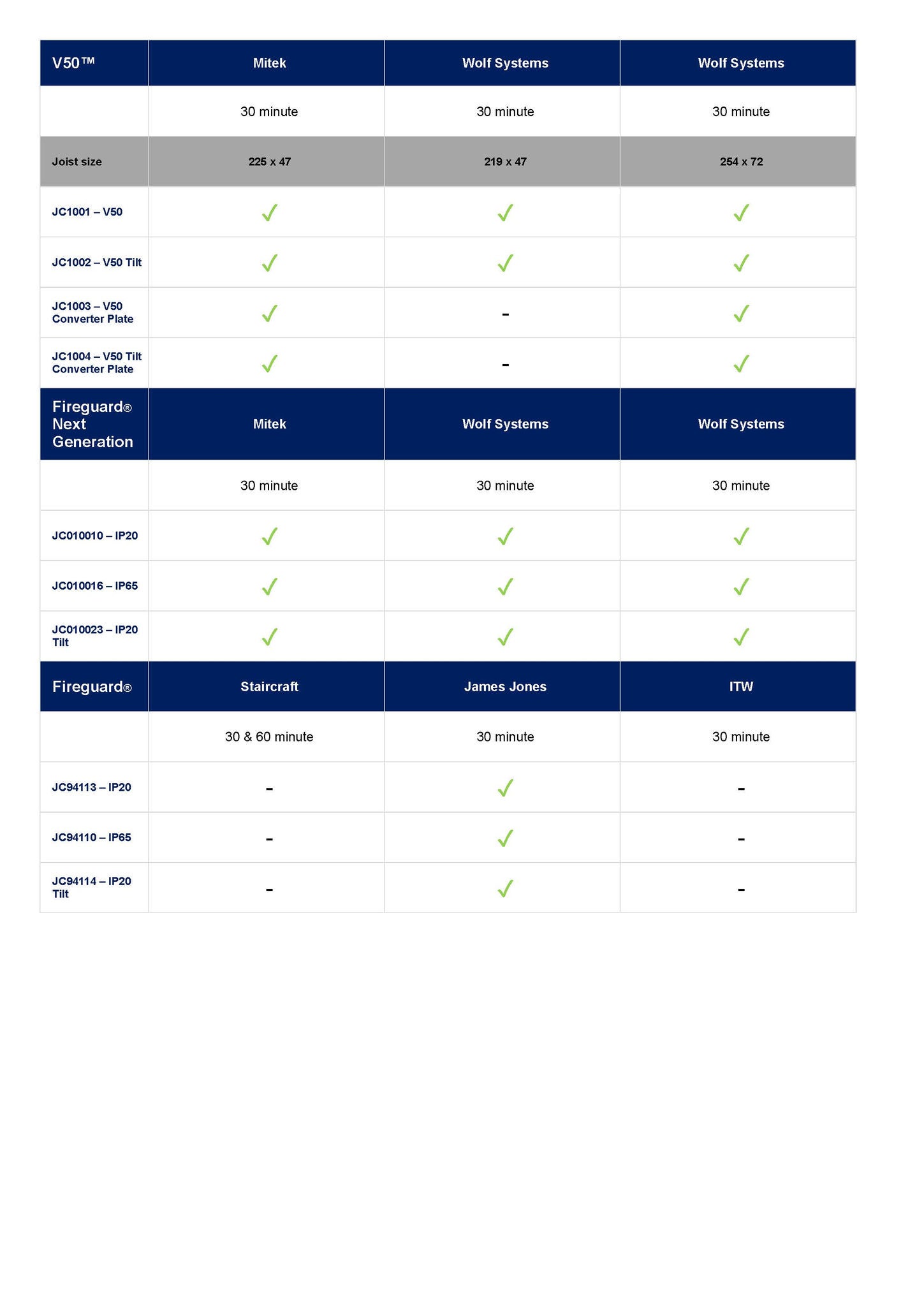

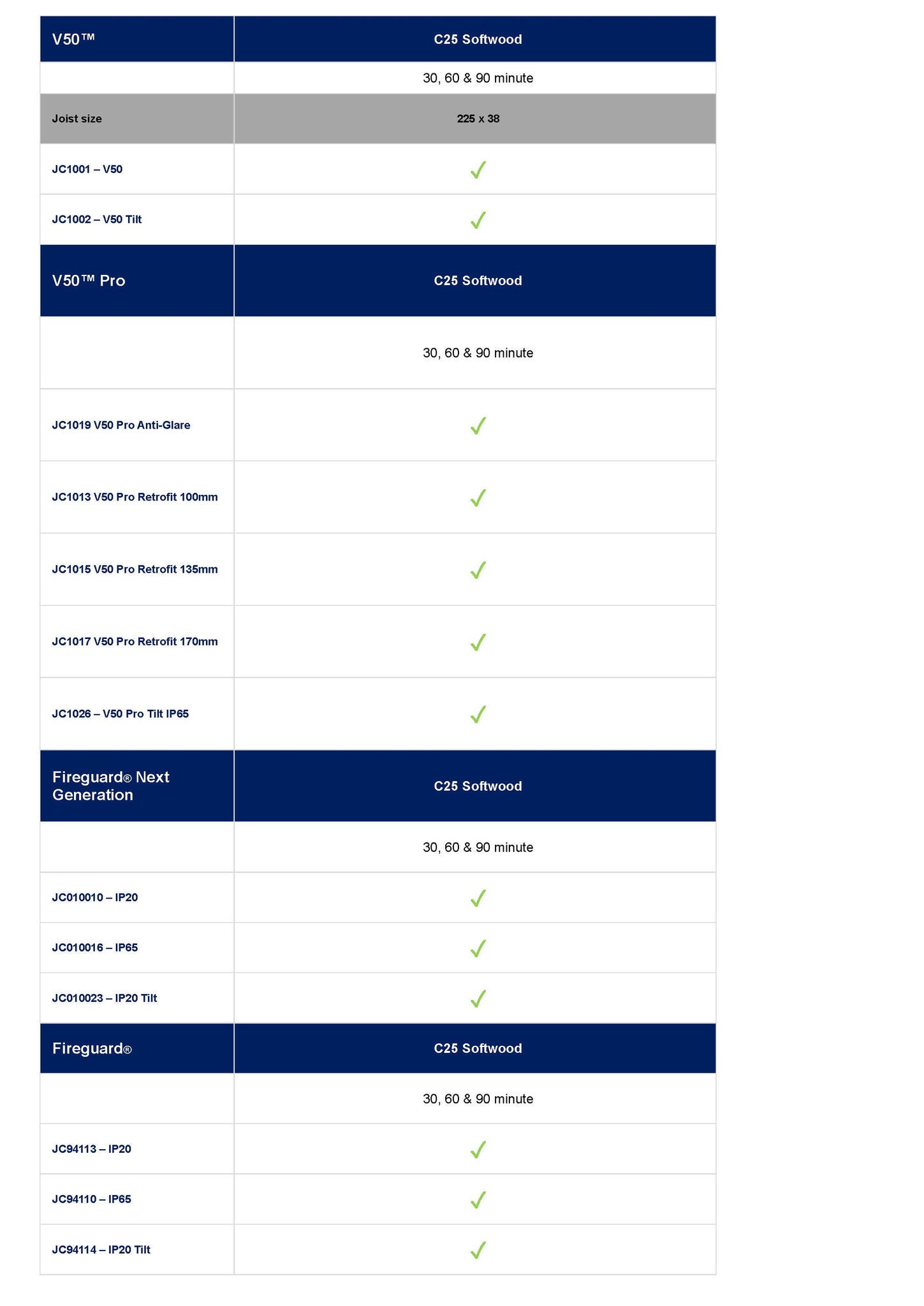

We are now proud to say all JCC fire-rated downlights are tested for use in solid, I-Joist and steel open web joist ceilings. For individual joist manaufacturers, please expand the links below, or visit the individual product pages for test certificates.

Our fire-rated downlights also meet Part L (Energy Efficiency), Part B (Fire Safety), Part C (Resistance to Contaminants and Moisture) and Part E (Resistance to Sound) of the UK Building Regulations.

I-Joists are strong, lightweight, "I" shaped engineered wood beams that meet current performance standards in the UK for domestic applications. I-Joists are comprised of top and bottom flanges, which resist bending. These flanges are jointed with a web, which provides rigidity and strength to the joist. The flange material is typically laminated or solid wood, and the web is made with plywood or OSB. The robust combination of flanges and webs results in a versatile, economical joist that is easy to install, durable and strong.

I-Joists provide considerable structural strength in relation to the volume of materials used. They can reduce the risk of bowing or buckling which provides a clear benefit for construction.

However, their construction performs very differently than a solid wood joist in the event of a fire, and as such, require separate and very specific fire testing.

The purpose of all fire rated downlight testing is to confirm that in the unfortunate event of a fire the integrity/strength of a ceiling is not compromised when downlights are installed, Depending on construction type a plasterboard finished ceiling without any downlights provides either a 30, 60 or 90 minute solid joist or 30 & 60 minute I-Joist rating,therefore, when holes are cut to accomodate downlights, the rating can be compromised. All JCC fire rated products are a ‘canned’ design and being pressed steel, the black ‘can’ of the product will remain in the ceiling preventing heat, flame or smoke passing into the voids for the required duration. This helps the ceiling to maintain its integrity and ensure safe evacuation or access for fire fighters.

If at the end of the test period, the ceiling construction has maintained its integrity and stays in place then this is the pass result required.

It is important that the downlight you have chosen will enable you to fully comply with Part B of the building regulations.

JCC I-Joist test certification is available in the Support/Downloads section on each of the products which carry this accreditation.

As mentioned above is it equally important that your chosen downlights not only meet the requirements of fire rating (Part B, Building Regulations) but where required they also meet the following UK building regulations and European standards:

All importers and manufacturers should be able to provide, upon request all the above documents to support the compliance of their products. All the above documentation is also available for the Fireguard® & V50™ on their respective product pages.

For information only.

It is the responsibility of the installer to ensure compliance with all relevant regulations.